Connected Packaging Solutions: Know Your Options

Connected packaging solutions provide new ways for customers to connect with your brand. Using a mobile device, customers can activate a special code printed on or within a product’s packaging and experience a digital world connected to your brand.

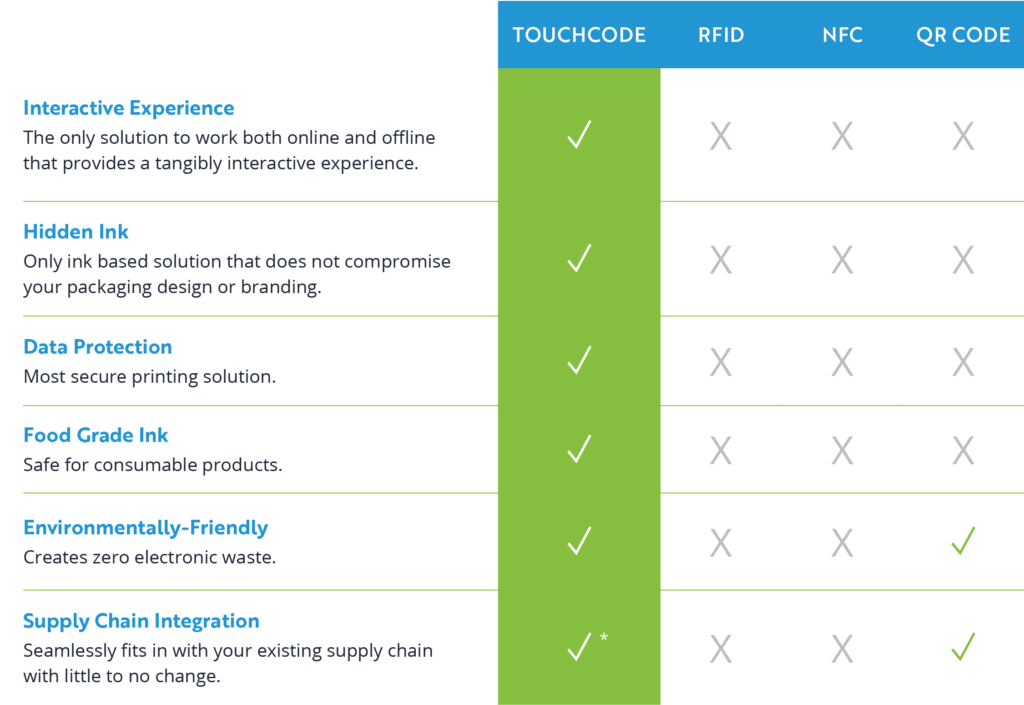

There are four leading types of technology that can be used in connected packaging applications: Optical (think QR codes), NFC, RFID, and Touchcode. It’s helpful to know how each of these technologies work and what their pros and cons are in specific applications. Let’s dive in.

Connected packaging technologies

Optical Technologies: QR codes & barcodes

Optical technologies use a visual indicator that, when optically scanned, allows for an action or engagement to take place. The most familiar optical technologies are QR codes and barcodes.

A QR code, short for Quick Response barcode, is a two-dimensional barcode, and a regular barcode is a machine-readable optical label. Both reveal information when scanned by a phone or barcode reader. You use barcodes at the grocery store when the checker scans your products, and QR codes appear in displays and on product packaging.

QR codes and barcodes are free to implement and can be printed by a regular color printer. They are visible on packaging and can be read by a camera or reading device by holding the object still, focusing on the QR code or barcode, and scanning with the device.

QR codes require the user to run a camera app or download a native app with camera function. Distance, lighting, and lens quality can impact readability. In most cases, without an app installed on the device, QR codes require online connectivity. Because most optical technologies are visible to the consumer, they can be copied or scanned by anyone who can see the product and don’t provide the most secure method of content delivery.

NFC

NFC, or Near Field Communication, is a communication technology based on a radio frequency (RF) field.

Implementing NFC technology can be pricey, considering the hard cost of the chips themselves, plus additional costs for programming or encoding the chips; potential offline assembly, which can’t always be done inline with existing manufacturing methods; and the potential costs of working with electronic products and waste.

In the past, NFC technology worked seamlessly on Android devices, but iPhone users had to turn it on. It’s important to note that some customers aren’t comfortable having NFC turned on at all times and view it as a security risk, which can present a hurdle for the technology.

NFC reading accuracy is about 100%, and NFC technology provides static content offline and dynamic content online. It’s a wonderful product for high security needs or product tracking; however, it’s not the best choice for sustainability campaigns because the electronic chips create waste.

RFID

RFID, or Radio Frequency Identification, uses electromagnetic fields to automatically identify and track tags attached to objects. Credit cards with microchips are an example of RFID technology.

Like NFC technology, RFID costs vary, depending on volume and the integration process; and RFID technology faces the same cost considerations: additional assembly processes, special converting processes, and special materials.

RFID reading accuracy is about 100%, and consumers can view static content offline and dynamic content online, similar to NFC technology. RFID is useful for in-store supply chain and logistics, or higher price point items, but it requires a dedicated reader. It is accessible for everyday use by consumers looking for information that’s readily available. RFID generates electronic waste, and because neither food products nor children’s products can include chips, RFID can’t be used in either of those product areas.

Touchcode

Touchcode is a printed technology that uses an invisible pattern or code designed for your application. The code is then printed on a product or package that can be scanned by a consumer’s mobile device to unlock content on an app or website.

Touchcode, as a fully printed technology, is very affordable, and no supply chain changes need to be made when implementing the Touchcode technology. Touchcode uses conventional printing methods available at any print facility. Touchcode is invisible to consumers and can be read on common multi-touch devices (mobiles and tablets) and dedicated readers, by sliding or holding and placing the Touchcode on the device screen. The reading accuracy is about 100%.

Touchcode offers both online and offline connectivity—online, via a website or app, and offline, via a native app. For example, Touchcode printed on a toothpaste package could be used on the Walgreens app, even if the user was in a subway tunnel. Touchcode provides interactive experiences via both apps and websites, so marketers can drive app downloads and website traffic by offering content exclusive to Touchcode-enabled digital locations and products.

Touchcode is fully recyclable, creating no electronic waste, and it is food grade safe, making it an ideal choice for connected food packaging and children’s products.

For example, Ferrero used Touchcode to promote a Kinder Surprise Egg for children. Touchcode-enabled trading cards placed in each product package provided consumers with access to a new digital experience—a game for a younger audience. Two different cards in each multi-pack of the special edition “Porsche” Kinder packs granted special access to games in which players competed to collect Porsche cards and could also be used in the quartet game. The app received four-star ratings in the iOS App Store and Google Play Store.

How invisible conductive ink can help your brand

Touchcode is an ideal choice for food packaging and children’s product applications, as well as sustainability promotions and budget-sensitive connected packaging initiatives. Touchcode is also a natural choice for products that are already being printed by conventional means.

Ready to learn how Touchcode’s connected packaging technology can help your brand create deeper relationships with customers? Contact us today.